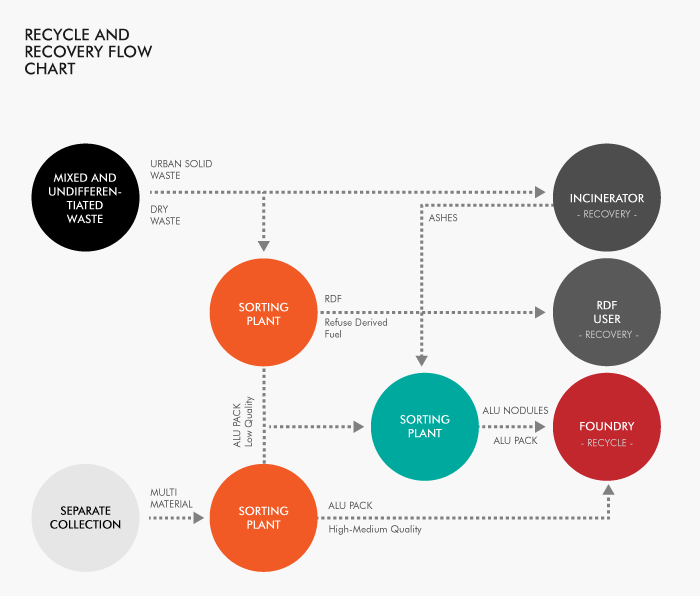

There are different flows in the management of aluminium packaging waste.

Waste separate collection is the basis for correctly disposing of the material. With this and after this phase there are other “steps” that packaging can go through at the end of its useful life.

The separate collection

With very few special exceptions, aluminium packaging is always collected with other kinds of materials using the multi-material system, according to procedures that vary depending on the facilities and plants working in the various regions.

Here is a general map of waste collection in Italy:

- “light multi-material” collection (metal and plastic packaging), carried out in parts of the regions of Lombardy, Piedmont, Friuli V.G., Veneto, Puglia, Calabria and Campania;

- collection with the “heavy multi-material” system (metal, glass and plastic packaging) commonly used in the regions of Calabria and Emilia Romagna and parts of Latium, Tuscany and Veneto;

- collection with the “glass-metals” system, commonly used in the regions of Val d’Aosta, Marche and parts of Liguria, Sardinia and Lombardy;

- collection of “metal packaging” alone, used in parts of the regions of Emilia Romagna and Trentino Alto Adige.

Mixed and undifferentiated waste

Many kinds of materials destined for separate collection end up in the bags normally used for non-recyclable waste. The aluminium fraction in this kind of waste can be retrieved and valorised using sorting technologies.

Sorting Plants

After the collection the material is transferred to special sorting plants where an eddy current separator is used to separate aluminium from other kinds of waste. The collected aluminium is pressed into bales so it is more easily transported to foundries, where it is recycled. The discarded material from the separation process is sent to incinerators or used for the production of EfW (Energy from Waste).

Incinerator

The so-called ‘black bag’ process of mixed and udifferentiated waste is started in incinerators with waste-to-energy facilities. The aluminium that is not included in bags destined for recycling is therefore recovered and energy obtained through combustion (energy value). Packaging elements that are less than 50 micron thick are completely burnt (producing energy) whereas thicker packaging, at the end of the process, is recovered from post-combustion waste and recycled.

EfW incinerator

Aluminium packaging and similar products can be separated from other waste destined for disposal before the EfW processes. In other cases, aluminium fractions with thickness below 50 micron and that are not separated before the process became an integrating part of the EfW/dry fraction.

Foundries

After the sorting process, the aluminium packaging bales are sent to be recycled in foundries. The material is pre-treated at a temperature of 500°C to remove varnishes or other adhering substances and then melted at 800°C to obtain liquid aluminium, which is turned into ingots and sheets, which in turn are used to make semi-processed items and new products. The recycled aluminium, which has the same properties and qualities of the primary aluminium, is used in the car industry, in the building industry and to produce household items and new packaging.