EU directives encourage rapid establishment of a circular economy which includes recycling of materials.

Easy to collect and 100% recyclable, aluminium packaging facilitates waste management and reduces the amount of CO2 released into the atmosphere. While also reducing food waste.

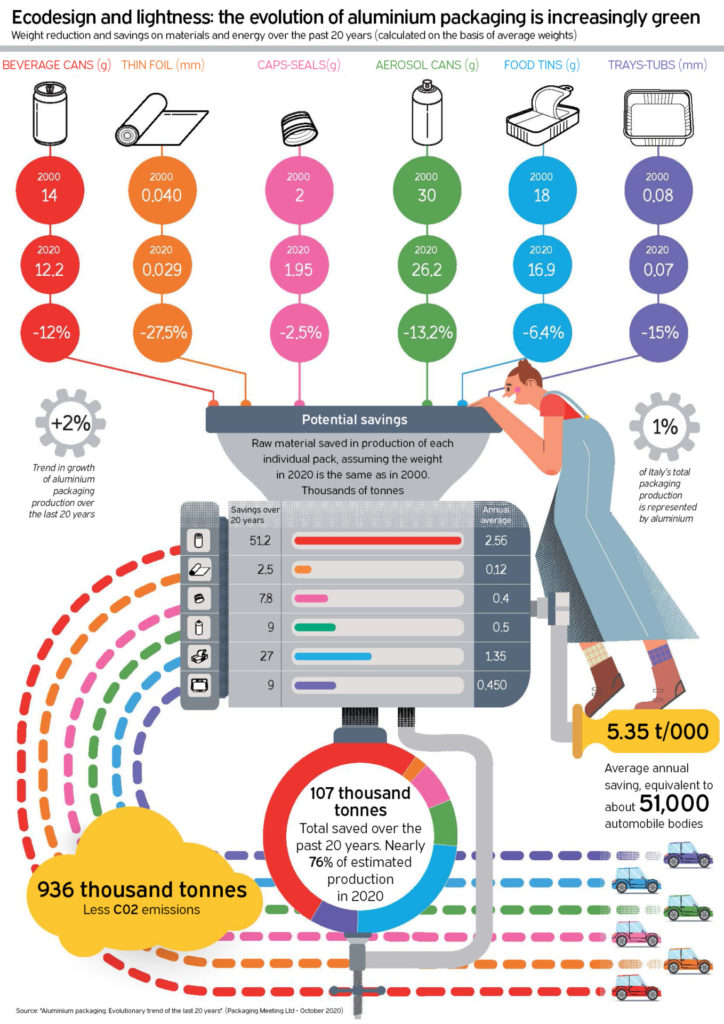

A recent study on “Aluminium packaging. Evolutionary trend of the last 20 years” highlights the progressive evolution of environmental production among CIAL member companies and their constant commitment to reducing the thickness of aluminium packaging produced.

The figure is alarming: more than 2.5 billion tonnes of waste are produced each year in the European Union. An immense amount, difficult even to imagine, let alone dispose of.

In March 2020, under the umbrella of the European Green Deal (a roadmap for achieving climate neutrality in Europe by 2050), the European Commission presented a plan of action for a new circular economy based on more sustainable product design and reduction of waste. This circular model of production and consumption involves sharing, reuse and recycling of existing materials and goods, and which goes beyond the typical linear model based on the ‘extract, produce, use and discard’ model, which has now become completely anachronistic.

With the aim of achieving a ‘circular economy’, the European Commission has, among other actions, approved a series of measures aimed at maximising the recycling of packaging, whatever the material of origin. Specifically, in the case of aluminium packaging, the target is 50% recycling by 2025 and 60% by 2030. Challenging goals from a supranational perspective, but in Italy, they have fortunately already been achieved and surpassed.

For many years now, the Italian aluminium recycling industry has been moving at record pace. Our country ranks third in the world, together with Germany and after the United States and Japan, in terms of the quantity of material recycled: over 70% of the material placed on the market.

This is partly thanks to the daily commitment of CIAL, the National Consortium for Aluminium Packaging, which has been working since 1997 toward the dual goal of sending aluminium packaging that has reached the end of its life cycle for recovery and subsequent reuse, while promoting initiatives to raise public awareness of the importance of aluminium recycling. With this in mind, CIAL promotes an evolved concept of sustainability, stimulating the cooperation of the various players involved in the aluminium packaging chain. It is a question of circular responsibility that invites everyone (producers, public administration and even individual citizens) to cooperate in actively to achieve overall collection and recycling targets.

Technological innovation: increasingly lightweight products to save on use of raw materials

One of CIAL’s priorities is to encourage its member companies to adopt sustainable practices that benefit the ecosystem around us. Emblematic, in this sense, are the data reported by the recent study ‘Aluminium Packaging. Evolutionary trend of the last 20 years’ (Packaging Meeting srl – October 2020) which highlight the progressive environmental evolution of member companies and their constant commitment, aimed, for example, at reducing the thickness and consequently the weight of the aluminium packaging produced – measured in grams, as it is a very light material by nature (see attached infographic).

- Beverage cans (33 cl) – The weight of a can fell from 14 g in 2000 to 12.2 g today, a decrease of 12%. This resulted in a saving of about 51.2 thousand tonnes of raw materials.

- Foil (chocolate/biscuit/cheese wrappers, foil for household and commercial use) – Since 2000, there has been a 27.5% reduction in weight due to reduction of thickness, resulting in an overall saving of about 2.5 thousand tonnes of aluminium.

- Caps-Seals – The weight of these items has also been reduced, by about 2.5% (average change among the different types). This average reduction has resulted in an overall saving of about 7.8 thousand tonnes over the last 20 years.

- Aerosol cans – In 2000, the average weight of aluminium aerosol cans was 30g. Over the last 20 years, the reduction has been around 13.2%, reaching an average weight of 26.2 g in 2020. The total amount of aluminium saved in 20 years is about 9 thousand tonnes.

- Food tins – In 2000, their average weight was 18g. Gradual reduction over the years (by about 6.4%) has resulted in an average weight of 16.9g in 2020. The total saving over 20 years is about 27 thousand tonnes of aluminium.

- Food trays and tubs – Over the last 20 years, the average thickness has been reduced from 0.08 mm to 0.07 mm, and the reduction in weight has been around 15%. This has saved a total of about 9 thousand tonnes of aluminium.

Adding up the results obtained for the various types of aluminium packaging analysed, a total of about 107 thousand tonnes of aluminium has been saved over the last 20 years, saving an average of 5.35 thousand tonnes a year. This has greatly reduced production costs and saved a considerable amount of energy.

100% RESPONSIBLE

Lightweight, non-polluting, and 100% reusable for an infinite number of times. Strong but ductile, tough but malleable, good-looking and durable… aluminium is used today in a variety of fields for the production of millions of products and various types of packaging. These intrinsic characteristics make it ‘responsible by nature’, a key ally for sustainable production and consumption models based on efficient use of natural resources. That’s right: aluminium is to all intents and purposes a ‘permanent’ material. Suffice it to say that over 75% of the aluminium ever made is still in circulation. Aluminium never loses any of its original properties, year after year, recycle after recycle. The socio-economic benefits are obvious.

LESS EXTRACTION AND LESS CO2

The process of extracting and using raw materials (whatever they may be) inevitably have a major impact on the environment and contributes to energy consumption and carbon dioxide (CO2) emissions. Over the past 20 years, progressive growth of recycling and reuse has made it unnecessary to extract the corresponding amount of new aluminium, saving more than 6,600,000 tonnes of CO2 emissions. Easy to collect and easy to recover, aluminium reduces waste upstream, in full compliance with the EU directives transposed in July and included in the Environmental Consolidation Act.

A BARRIER EFFECT AGAINST FOOD WASTE

Different formats, different weights and sizes, plenty of possible uses. Cans, tins, trays. Canisters, caps and tubes, pastry cases. Even ordinary rolls of wafer-thin foil… we all use aluminium packaging in countless ways every day to contain, protect and preserve food and other products.

More than any other material, aluminium offers an excellent barrier against light, bacteria, air, oxygen and steam. When used as packaging for food and drink, it is therefore very useful for preserving the product contained, minimising the production of organic waste and making an important contribution to reducing food waste. In addition, in the case of delivery and takeaway food (a method of buying/consuming food that is becoming increasingly popular, not least because of the current pandemic), ‘classic’ aluminium trays and tubs ensure that the food contained remains at the ideal temperature for a long time. An additional advantage that is not to be underestimated.